OLI is founded

Founded in 1954 in Aveiro, OLI Sistemas Sanitarios S.A. started as a small family organisation and persued its path throughout different areas of business.

Integration with the Silmar Group

In 1993, the company became part of the Silmar Group (formerly known as Fondital). Headquarted in Italy, it operates in four sectors: plumbing, drainage, heating and aluminium. The Group counts 1589 employees and has since reached an annual turnover of 1 billion dollars.

Mass production of the dual flush

23 years ago, OLI innovated by mass producing the dual-flush system, which today is part of most cisterns worldwide. This innovation, used by most companies is responsible for reducing water consumption by 50%.

SM15 by Souto de Moura

Eduardo Souto de Moura is a renowned Portuguese architect who has been presented with various international awards, such as, the Gold Medal of Heinrich Tessenow Foundation in 2001; the Pritzker Award in 2011; the Wolf Prize of Arts in 2013; just to name a few. In 2001, in collaboration with OLI, Souto de Moura developed the SM15 flush plate.

SM15 is a tempered white glass flush plate, 147mm by 147mm, and is ideal for a smooth application on walls covered with traditional Portuguese tiles. The SM15 is installed surface-even with the wall for a seamless and elegant look.

OLI implements Kaizen

OLI begins the implementation of the continuous improvement system from the Kaizen Institute. Continuous improvement has a direct and intrinsic relation in the optimization of processes that consequently lead to an increase in production. After implementing Kaizen, productivity increased by 30%, work in progress decreased by 30% and both final product stock and time to market reduced by 40%.

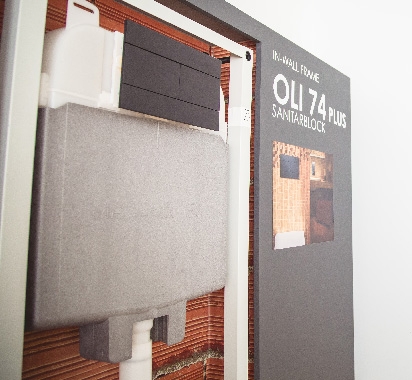

INO-X designed by Romano Adolini

The INO-X collection is a collaboration with Italian Architect Romano Adolini, an influential figure in bathroom design.

The result is a simple, elegant flush plate: A precise laser-cut, simple 22mm thick sheet of steel. This philosophy generated four models made of essential forms, drawn from squares and circles.

Trumpet by Siza Vieira

World-renowned architect and winner of several internaltional awards: 1992 Pritzker Prize; 2001 Wolf Prize of Arts; 2012 Golden Lion for Lifetime Achievement and 2014 Fritz Hoger award just to name a few, Alvaro Siza Vieira collaborated with OLI to design the Trumpet flush plate, an elegant design perfectly characterizing the pistons of a trumpet. Inspired by the instrument played by the great maestros, Siza created the harmonious design of this flush plate.

New state of the art life-test laboratory

The motto at OLI is simple: “Anticipate needs. Find solutions for the future”. With this in mind, a major investment in RDI was the complete renovation of our testing laboratory, which is now equipped with the latest technology that will allow us to be at the forefront when it comes to research and innovation. The lab is divided into two distinct interacting areas: half of the posts are exclusively allocated to tests and standards that permit different product certifications in markets. The other stations are focused on the future, and test products with different levels of water hardness, with rainwater and seawater. With the awareness that water is an increasingly scarce resource, today, and surely in the future, we at OLI do everything in our power to protect against water shortages. We do not consider our efforts in the area a cost, instead we perceive them as an investment in the quality of life for everyone.

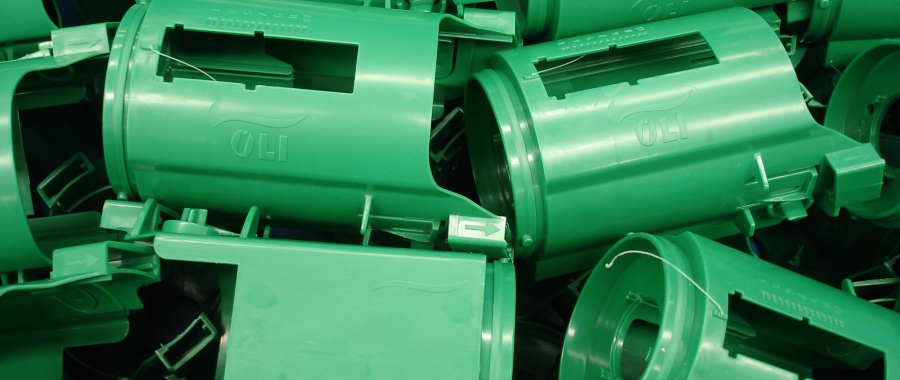

New Mold Factory Construction

The construction of a new mold factory aims at increasing our production capacity by 50% and at increasing the quality of complex and demanding molds intended for hydro-sanitary and automotive industries all over the world.

OLI today

OLI's entire value chain is controlled from their facilities, that have an area of 882,640 sq ft. Beginning with the conception of ideas to their industrialization and production, ending in their commercialization in more than 80 countries around the world. The growing interest in a contemporary design and in new technologies and materials, always with a focus on water efficiency and respect for the environment, has made OLI a world reference and a brand of excellence. With about 401 employees and 56.3 million Euros in sales in 2018, OLI currently has a yearly production of approximately 2 million cisterns and 2.8 million mechanisms. This makes OLI one of the major producers in Europe for mechanisms for the ceramic industry, as well as concealed and exposed cisterns. Currently, OLI is the only Portuguese company producing concealed cisterns.

2020

Thanks to its innovative capacity and fast acting in production, OLI makes its industrial contribution to the national fight against the Covid-19 pandemic, producing a face shield that will help protect health professionals in the treatment of patients with the new coronavirus.

163 000 face shield produced which 61 000 were donated

LESS IS MORE WINS DESIGN AWARDS

Red Dot Design Award, IF Design Award and Archiproducts Design Award were the awards won in 2021 by the LESS IS MORE flush plate.

LESS IS MORE is the name of the flush plate whose design is inspired by the history of the mechanism and the desire to give it an innovative shape, projecting it into the future.

Made of stainless steel, with an eclectic and functional identity, LESS IS MORE was designed by the architect Alessio Pinto who, in addition to being inspired by the history of the mechanism, used the iconic principle "Less is More" by Ludwig Mies Van Der Rohe.

10th Expansion of the OLI Industrial Complex

OLI has expanded its industrial complex in Portugal with the construction of a new logistics warehouse. Sustainability and energy self-sufficiency were taken into account in this project, which included the installation of photovoltaic panels on the roof and façade of the warehouse, which in the future will be completely automated.

The main objective was to boost process efficiency in the distribution and supply chain operation by providing a faster and more effective response.